Execute tasks, adapt to new knowledge, control risks

Project execution is underway - work the plan, manage change

Your project execution is underway! As the project manager, you were probably heavily involved in developing the tactical project plan; even if you were not, you are now accountable for delivering the expected results. How can you maximize your chance for success in accomplishing the ‘change for the better’ promised by your project?

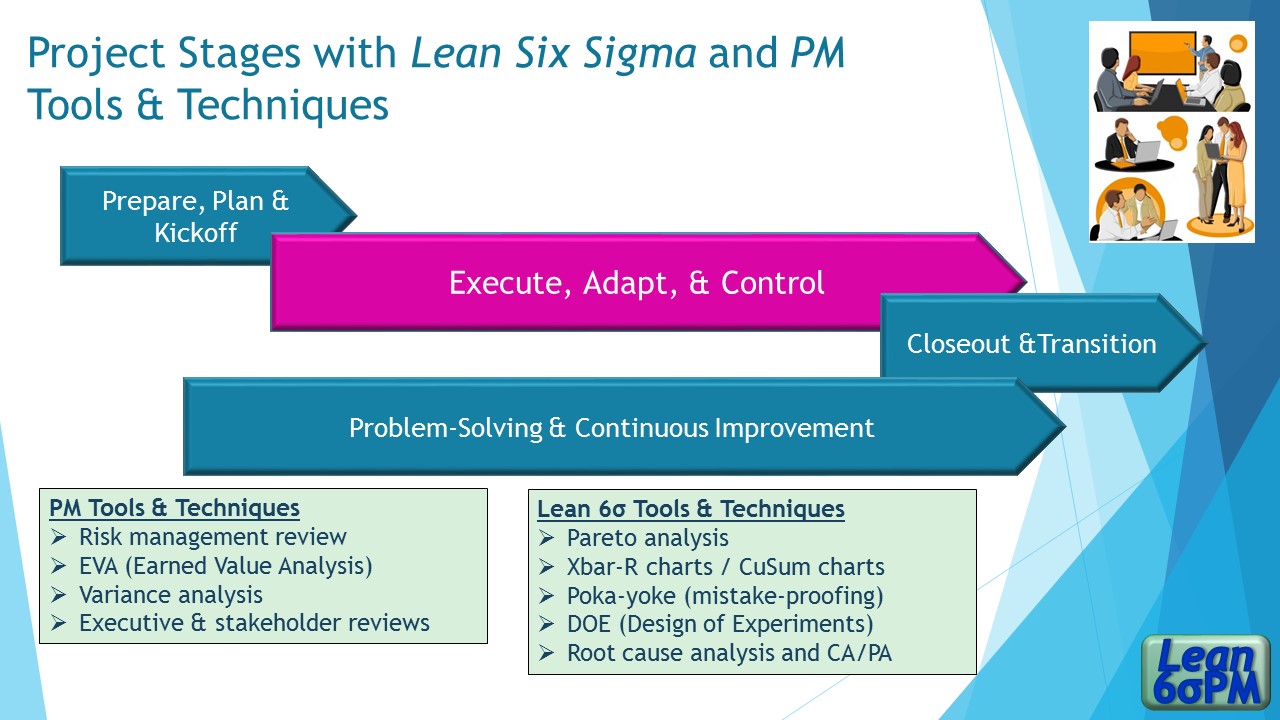

In military endeavors, there is a familiar saying that “No battle plan survives the first contact with the enemy.” Unexpected events will undoubtedly interfere with your advanced technology project plan as well. In manufacturing operations, product engineering, and cross-functional program projects, it is important to have the latitude, breadth of skills, and the tools to be able to adapt to events as they unfold. A few of the tools available to the project leader to facilitate controlling the factors that are known, and adapting to risk factors which may arise, are shown in the nearby graphic.

Project Execution is about getting it done, bringing the plans to fruition. Adaptation occurs through the duration of the project, as new knowledge is acquired and applied, risks are continually reassessed, and project tasks are completed. Control entails setting up the measures of success, and providing data and indicators to help the project team stay on track while keeping stakeholders apprised of progress.

The Project Manager must continually anticipate the next 2 to 5 steps in the project flow, identify and remove roadblocks, and make sure the needed resources are available. Easy to say, not so easy to do for the duration, as other business needs periodically interfere with your project’s flow and threaten to draw off key resources at inopportune times.

Your project execution is underway! As the project manager, you were probably heavily involved in developing the tactical project plan; even if you were not, you are now accountable for delivering the expected results. How can you maximize your chance for success in accomplishing the ‘change for the better’ promised by your project?

In military endeavors, there is a familiar saying that “No battle plan survives the first contact with the enemy.” Unexpected events will undoubtedly interfere with your advanced technology project plan as well. In manufacturing operations, product engineering, and cross-functional program projects, it is important to have the latitude, breadth of skills, and the tools to be able to adapt to events as they unfold. A few of the tools available to the project leader to facilitate controlling the factors that are known, and adapting to risk factors which may arise, are shown in the nearby graphic.

Project Execution is about getting it done, bringing the plans to fruition. Adaptation occurs through the duration of the project, as new knowledge is acquired and applied, risks are continually reassessed, and project tasks are completed. Control entails setting up the measures of success, and providing data and indicators to help the project team stay on track while keeping stakeholders apprised of progress.

The Project Manager must continually anticipate the next 2 to 5 steps in the project flow, identify and remove roadblocks, and make sure the needed resources are available. Easy to say, not so easy to do for the duration, as other business needs periodically interfere with your project’s flow and threaten to draw off key resources at inopportune times.

When it's time to take Action --

If you’re reading this, you are probably running an advanced technology product introduction, or a manufacturing process capability enhancement project, or something similar. Successful implementation in the Execute, Adapt, and Control stage (or any stage) requires focus on the critical few most important actions that need to be taken.

A personal story: Years ago, I attended my first formal project management course, a 3-day seminar offered in a local venue by a pair of trainers who specialized in project planning for federal government programs. I vividly remember them offering us the sincere advice that the best situation we newbie project managers could have would be to be hired to develop the project plan, but not have to manage the project itself. Why? Because, they said, creating the plan was easy, but running the actual project might take years and would be extremely difficult!

Well, for those of us in the real world, ducking the hard projects is never an option.

Go for Extraordinary!

If you are not blessed with one of the easy projects, fear not. Ask and seriously discuss the right questions with your project team, and thoughtfully consider the responses to provide guidance to execute your planned tasks, adapt to unexpected events, and establish the control criteria to stay on track and to recover when needed.

Although every project is unique in some way, the questions typically considered throughout project execution center on the daily or weekly project cadence, such as:

♦ Team member roles and responsibilities, and task status

♦ Availability of required staff members and expertise for current tasks

♦ Reporting to the business leaders, including escalations if required

This level of focused attention is sufficient for most project managers to lead the team to successful completion.

Successful completion is good enough for 85-90% of PM’s and their executive leadership.

Exceptional project leaders, the top 10% or so who refuse to settle for good enough, achieve higher levels of performance by employing questions and practices inspired by lean six sigma and the PDSA (Plan-Do-Study-Adjust) framework. The objective of PDSA is continuous improvement: that is, taking actions to make the project itself, and the business unit or PMO by extension, better next week and next month than it is now. How?

Plan: Ask targeted questions about an important project attribute, and make a decision.

Do: Make a change to try to improve the attribute.

Study: Assess the result of the change.

Adjust: Make it permanent if it works, or else initiate another PDSA cycle.

In short, Lean Six Sigma Project Management.

Interested in making improvements in project execution, adaptation, and control?

Ping me at Dann@Lean6sigmaPM.com to find out how to employ PDSA questions to drive higher performance in your project team.

If you are not blessed with one of the easy projects, fear not. Ask and seriously discuss the right questions with your project team, and thoughtfully consider the responses to provide guidance to execute your planned tasks, adapt to unexpected events, and establish the control criteria to stay on track and to recover when needed.

Although every project is unique in some way, the questions typically considered throughout project execution center on the daily or weekly project cadence, such as:

♦ Team member roles and responsibilities, and task status

♦ Availability of required staff members and expertise for current tasks

♦ Reporting to the business leaders, including escalations if required

This level of focused attention is sufficient for most project managers to lead the team to successful completion.

Successful completion is good enough for 85-90% of PM’s and their executive leadership.

Exceptional project leaders, the top 10% or so who refuse to settle for good enough, achieve higher levels of performance by employing questions and practices inspired by lean six sigma and the PDSA (Plan-Do-Study-Adjust) framework. The objective of PDSA is continuous improvement: that is, taking actions to make the project itself, and the business unit or PMO by extension, better next week and next month than it is now. How?

Plan: Ask targeted questions about an important project attribute, and make a decision.

Do: Make a change to try to improve the attribute.

Study: Assess the result of the change.

Adjust: Make it permanent if it works, or else initiate another PDSA cycle.

In short, Lean Six Sigma Project Management.

Interested in making improvements in project execution, adaptation, and control?

Ping me at Dann@Lean6sigmaPM.com to find out how to employ PDSA questions to drive higher performance in your project team.