Problem-Solving and Continuous Improvement

Problem Solving and Continuous Improvement - Two Sides of the Same Coin

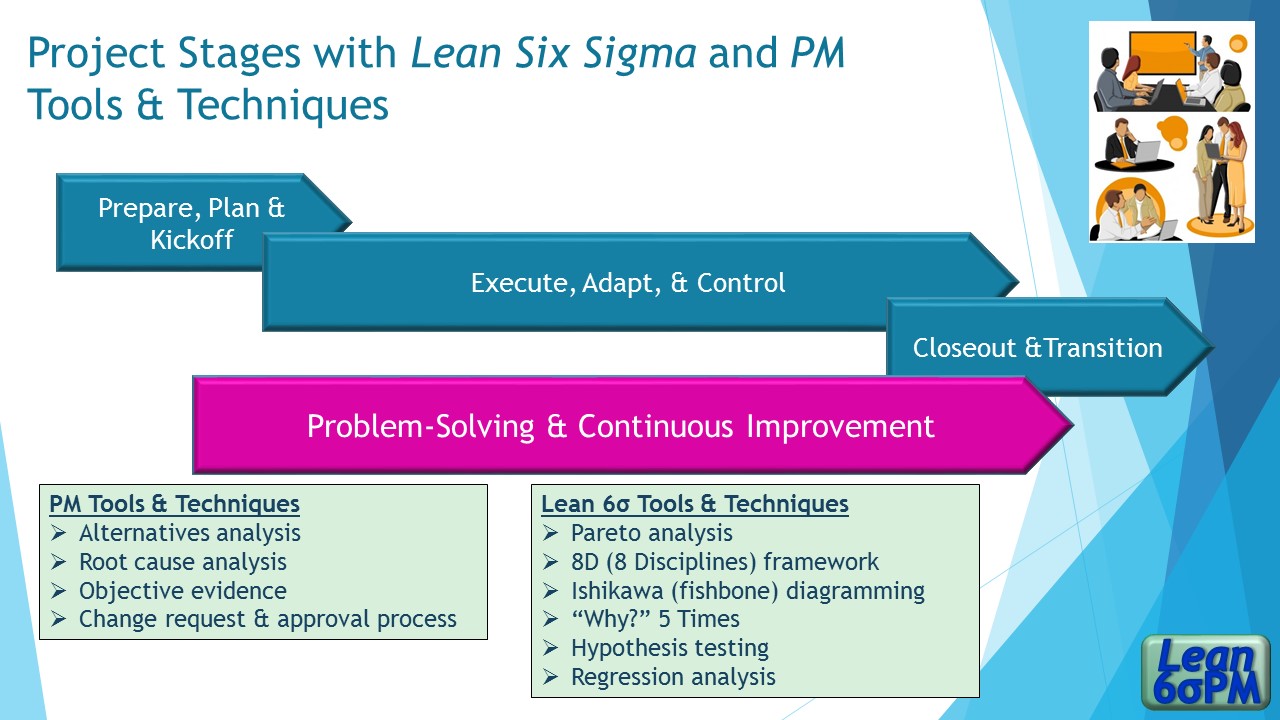

Complex technical change projects are inherently risky; problems will arise that may not have been considered during risk planning. A design verification test may fail; a supplier may be late delivering a critical piece of process or test equipment; a competitor may announce a new product feature that will adversely affect your new product’s market acceptance.

Furthermore, any change project involves uncertainties in the planning stage that, during execution, may result in schedule slips, resource allocation conflicts, and/or unforeseen costs.

Lean Six Sigma (LSS) problem solving tools – 8D analysis, cause-effect analysis, root cause and corrective action, and others – provide a disciplined approach to solving complex technical problems. Following LSS practices helps teams move methodically from observed symptoms to drill down to the source of problems, in order to implement permanent solutions.

LSS continuous improvement methods – PDSA, kaizen, 5-Why, and others – can be proactively applied to manage project flow, minimize schedule disruptions, recover time lost in early project phases, and document decisions and actions taken.

Learning, applying, and mastering certain Lean Six Sigma PM techniques advances the team and business organization in several ways:

♦ From patching symptoms, to permanently solving problems

♦ From over-reliance on one expert, to building skills across the business

♦ From accepting project delays, to having confidence that early delays can be recovered

In short, from working hard to working smart.

Complex technical change projects are inherently risky; problems will arise that may not have been considered during risk planning. A design verification test may fail; a supplier may be late delivering a critical piece of process or test equipment; a competitor may announce a new product feature that will adversely affect your new product’s market acceptance.

Furthermore, any change project involves uncertainties in the planning stage that, during execution, may result in schedule slips, resource allocation conflicts, and/or unforeseen costs.

Lean Six Sigma (LSS) problem solving tools – 8D analysis, cause-effect analysis, root cause and corrective action, and others – provide a disciplined approach to solving complex technical problems. Following LSS practices helps teams move methodically from observed symptoms to drill down to the source of problems, in order to implement permanent solutions.

LSS continuous improvement methods – PDSA, kaizen, 5-Why, and others – can be proactively applied to manage project flow, minimize schedule disruptions, recover time lost in early project phases, and document decisions and actions taken.

Learning, applying, and mastering certain Lean Six Sigma PM techniques advances the team and business organization in several ways:

♦ From patching symptoms, to permanently solving problems

♦ From over-reliance on one expert, to building skills across the business

♦ From accepting project delays, to having confidence that early delays can be recovered

In short, from working hard to working smart.

When it's time to take Action --

Here’s some disconcerting news you probably already know. The number of possible problems that can occur during your project is infinite. And your ability to know and plan fully for all of them in advance is zero!

Chances are you have a PMP® certification, and access to the project manager’s most cited reference, the PMBOK®. Good – that’s an excellent source of information! Let’s see what it says about problem solving.

Uh-oh. A few sentences in 7 locations. Nothing that is actionable, I’m afraid.

What about continuous improvement? Even less, it turns out.

How about available Project Manager training?

Uh-oh again. For example, one of the most widely available PM training courses offers this 6-step approach to problem solving in your project.

(a). Only focus on the important issues.

(b). Understand and state the problem.

(c). Prioritize, if there are multiple problems.

(d). Don’t spend time on unimportant things.

(e). Sometimes the best answer is to do nothing.

(f). If you need help, ask for it.

Go for Extraordinary!

I don’t want to be there when your VP of Operations presses you about how you’re planning to resolve the 84% failure rate at final test on your new product pilot build, and you offer up answer (d) or (e)!

The book, Shuttle, Houston! My Life in the Center Seat of Mission Control, by Paul Dye, (Hachette Books, 2020) has a thought-provoking section about problem solving during manned space flight missions in the Space Shuttle program. Sub-titled “The First Answer is Always Wrong,” the section describes “the tendency of flight controllers to want to solve every problem within milliseconds of seeing something happening in their system.” Frequently, however, the first observed anomaly is not by itself indicative of the underlying cause; other observations have to be made that in most cases lead to a small number of possibilities from which to choose a course of action. For that reason, NASA emphasized “fast thinking but slow action,” recognizing the timetable available for deciding and acting on a solution. That timetable is inevitably short, but it’s not milliseconds short.

The rush to judgment is not confined to space flight programs. For a down-to-earth example, see the case study “Product Upgrade Pre-launch Out of Box Failure (OOBF)”. In that situation, the fastest thinking senior leaders focused first on ‘defective lithium batteries’ and second on ‘defective memory chips’ provided by their suppliers as the cause of the OOBF. Reading the case, you will see that taking action on either or both of those obvious – but wrong – causes would have meant weeks of fruitless activity, leaving the organization with the same problem in the end.

Consider, then, the problem solving tools and techniques developed by Lean Six Sigma practitioners. As a project manager, you could enroll in training for a green or black belt if you have math, statistics, and technical skills attained with an engineering degree or MBA. By all means, do it. That is a very useful skill enhancement for a PM, long term; unfortunately, it won’t happen in time to save your current project.

For today’s problems and challenges, focus on a couple of LSS methods, including our old friend PDSA and a few related useful tools.

Ping me, Dann@Lean6sigmaPM.com, to discuss your immediate issues, and how to employ LSS problem solving and continuous improvement tools to get your project back on track.

I don’t want to be there when your VP of Operations presses you about how you’re planning to resolve the 84% failure rate at final test on your new product pilot build, and you offer up answer (d) or (e)!

The book, Shuttle, Houston! My Life in the Center Seat of Mission Control, by Paul Dye, (Hachette Books, 2020) has a thought-provoking section about problem solving during manned space flight missions in the Space Shuttle program. Sub-titled “The First Answer is Always Wrong,” the section describes “the tendency of flight controllers to want to solve every problem within milliseconds of seeing something happening in their system.” Frequently, however, the first observed anomaly is not by itself indicative of the underlying cause; other observations have to be made that in most cases lead to a small number of possibilities from which to choose a course of action. For that reason, NASA emphasized “fast thinking but slow action,” recognizing the timetable available for deciding and acting on a solution. That timetable is inevitably short, but it’s not milliseconds short.

The rush to judgment is not confined to space flight programs. For a down-to-earth example, see the case study “Product Upgrade Pre-launch Out of Box Failure (OOBF)”. In that situation, the fastest thinking senior leaders focused first on ‘defective lithium batteries’ and second on ‘defective memory chips’ provided by their suppliers as the cause of the OOBF. Reading the case, you will see that taking action on either or both of those obvious – but wrong – causes would have meant weeks of fruitless activity, leaving the organization with the same problem in the end.

Consider, then, the problem solving tools and techniques developed by Lean Six Sigma practitioners. As a project manager, you could enroll in training for a green or black belt if you have math, statistics, and technical skills attained with an engineering degree or MBA. By all means, do it. That is a very useful skill enhancement for a PM, long term; unfortunately, it won’t happen in time to save your current project.

For today’s problems and challenges, focus on a couple of LSS methods, including our old friend PDSA and a few related useful tools.

Ping me, Dann@Lean6sigmaPM.com, to discuss your immediate issues, and how to employ LSS problem solving and continuous improvement tools to get your project back on track.