Let's Do It My Way, Boss!

Here’s a way to help the people you lead develop effective problem-solving skills. Called ‘Lean A3 Problem Solving,’ it produces much better decisions than arguing, arm-wrestling, or rock-paper-scissors.

by Dann Gustavson

The Setup

If you have been a technical leader for more than a few months, you have undoubtedly had this situation arise. Two of your direct reports are engaging in an argument of sorts about how to proceed on solving a problem. Day by day, they each get increasingly “dug in” to their respective positions, and are not inclined to decide on one best solution on their own. Friday afternoon at 3:00 they barge into your office to bring you the problem. Each side states their case, pointing out the merits of their viewpoint, and for good measure, subtly informing you of their co-worker’s logical errors and character flaws, smiling throughout. You hear them out, you find nothing clearly superior or drastically wrong with either of their proposed solutions. You are their leader, and they eagerly await your decision, so they will know which one of them “wins” and which one “loses.”

Show of hands: how many think you should pick side one? How many pick side two? How many tell them to go away so you can think about it for a day or two before deciding?

Surprise! It’s a trick question; those choices are either wrong answers or very wrong answers. What you don’t want is to choose one position, and thereby create a Win-Lose outcome, teeing up another showdown in the near future. It is extremely rare that there is no room for compromise or better yet, synergy.

But what about choice 3? What really happens if you say you’ll think about it and then decide? It means that you have accepted responsibility for a problem that should be theirs, not yours, to resolve. Don’t fall into that trap.

So what do you do instead? Try Lean A3 Problem Solving.

Here’s a suggestion from the Lean Six Sigma leaders’ playbook: Involve your colleagues in a little Lean A3 Problem solving exercise. That might seem time-consuming, and therefore fraught with Non Value-Add (NVA), but it is not nearly as wasteful as arbitrarily picking either of the choices presented, and then dealing with the fallout for a long time to come. Been there, done that; it’s exhausting.

Start by sketching out the A3 on 11”x17” paper (that’s ‘A3’ size, hence the name) with the team members, or use your whiteboard if you prefer. Writing things down as you work through it allows all of you to focus on the problem, not on the people.

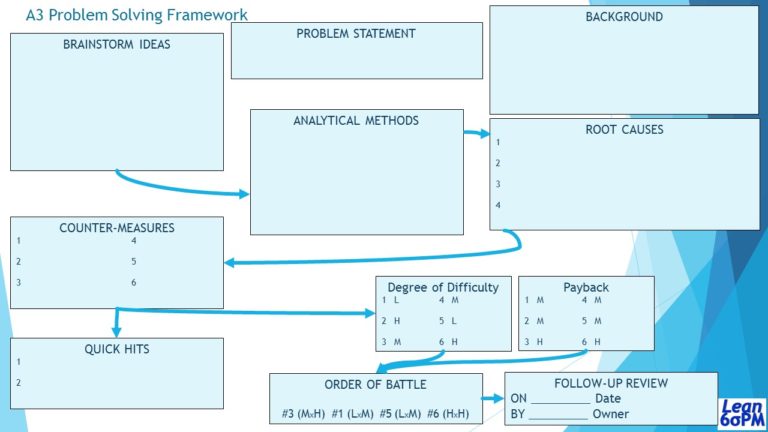

The graphic nearby illustrates the elements that typically go into an A3 Problem Solving diagram. The topics are not rigidly defined – use what makes sense for your situation, as long as it provides a roadmap to go from writing the Problem Statement to implementing the countermeasures or corrective actions. And ideally, don’t pull out a pre-printed form and make it a fill-in-the-blanks exercise; use it as a map to structure the group’s thinking process and dialogue to help new ideas percolate. The A3 in the example was originally created on a whiteboard, moving sequentially through the steps from Problem Statement to Quick Hits and Order of Battle. Over the years the method has helped my teams resolve many product design, quality, and manufacturing system performance problems.

How do you develop an A3 Problem Solving chart?

Start with timing. For most problems, strive to finish the A3 activity in 2 brief meetings on 2 days. Day 1 is to lay out the boundaries: problem statement, brainstorming and some analysis to move toward root causes. Then on Day 2, review the analysis and root causes after having a day or two to reflect on what you did and maybe to investigate some ideas a bit further. Then evaluate the possible root causes on your A3 and develop a countermeasure for each one that your team deems to be a root cause. It is possible one of the countermeasures can be implemented almost immediately (“Quick Hit”). If so, just do it! For others, however, there is some associated effort and probability of success in mitigating the root cause. These are the “Degree of Difficulty” and “Payback” in the A3 guide graphic. Don’t obsess over these; using Low – Medium – High is sufficient most of the time.

The Order of Battle combines the Difficulty and Payback to decide what to do first, second, etc. Low Difficulty x High Payback should get done first, Low (or Medium) x Medium next, etc. High Difficulty x Low Payback should probably be dropped from consideration. Ask for or assign volunteers to implement each countermeasure and set up a review mechanism to confirm implementation and gauge the effectiveness of the solutions.

What are the Benefits to using Lean A3 Problem Solving?

Glad you asked! Using this method provides several benefits. It’s a way to complete the decision and agree on the path forward quickly, including who owns what actions. It discourages making a hasty “gut-feel” decision based on symptoms without understanding causes, and therefore having the problem recur. It permits a small team to pull out many ideas for solving the problem so, together, you can evaluate them and choose the best one. The main benefit, which will get more pronounced each time you use it, is that it results in better solutions and a higher-performing team.

At the end of your second-day meeting, take 3 minutes to rate yourselves concerning the process you have gone through, from 1 (poor) to 5 (great). Let the participants express their thoughts in a few words, and summarize them on the whiteboard or paper A3 chart. Capture the completed A3 diagram with your phone camera and keep the photo in your team shared folder or workspace data wall for future reference.

OK, Dann - What's My Take-away?

If one of your leadership ground rules is to nurture and build relationships with the people you work with, and to develop their interpersonal skills as well as your own, then seeking Win-Win common ground solutions – through synergy or compromise – is preferable to Win-Lose, Lose-Win, or Lose-Lose decision-making. The best outcome will probably involve something from both choices initially presented to you, enhanced by new ideas that became evident by opening up the multi-way dialogue, which is what the Lean A3 Problem Solving technique is designed to do. And that, by the way, is pretty much the definition of synergy. Plus, you will then have at least two more people who have the A3 problem solving methodology in their toolbox for use next time a thorny problem arises.

It probably goes without saying, but I’ll say it anyhow. If the building is on fire, don’t engage in an A3, just pull the alarm and get everyone out! Short of that, why not give Lean A3 Problem Solving a try?

One more example of Next Level Leadership!

Dann Gustavson, PMP®, Lean Six-Sigma Black Belt, helps Program Managers and their teams achieve superior results through high-impact program execution. Prepare, structure, and run successful programs in product engineering, manufacturing operations (including outsourcing), and cross-functional change initiatives.

Contact Dann@Lean6SigmaPM.com.